Baseline Safety Standards

Baseline Safety Standards

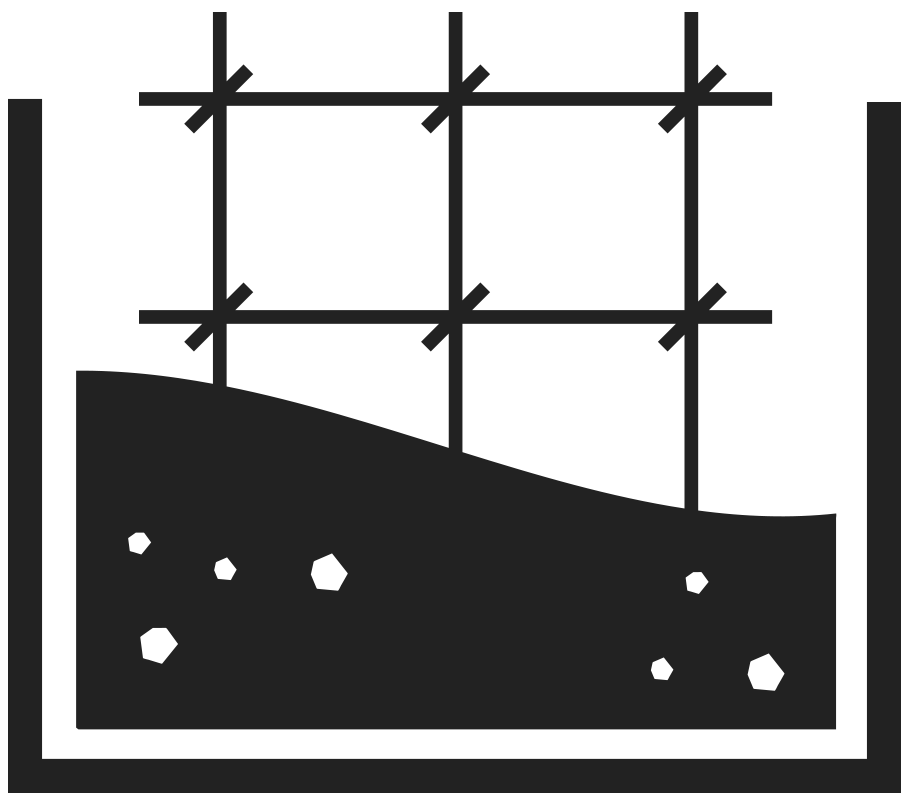

Formwork and Falsework

Minimum RequirementsFormwork and falsework are temporary structures that are used during construction and removed once a Structural Engineer responsible for the design in conjunction with the formwork engineer verify in writing that the permanent structure is self-supporting

-

Traditional/conventional timber formwork (e.g., steel frames, timber bearers, plywood decking)

-

Proprietary table Form Systems with handrail installed before being placed in position

-

Proprietary / modular formwork systems (e.g., Peri Deck, Airodek).

-

All materials and equipment used in formwork must be fit for the intended purpose, meet design specifications and comply with relevant Australian Standards, evidence of which should be made available by the supplier. Proprietary systems should not be mixed and matched unless approved by a Structural Engineer

-

Falsework may be constructed from prefabricated modular scaffold components, provided the structure is capable of withstanding the loading in AS 3610 series and such loading is permitted by the component manufacturer

-

Install handrails and edge protection to manage fall from heights risk in accordance with HRS – Working at Heights

-

Installation of Penetration covers where there are open penetrations

-

Work at Heights Permits to be approved prior to commencing works above 2 metres, refer to the Working at Heights High-Risk Standard

-

A Safe Work Method Statement shall be provided for all high-risk construction work conducted as part of formwork / falsework scope of works

-

Structural components, including frames specifically intended to support formwork, do not require design registration. However, if traditional prefabricated scaffolding is used as part of the supporting structure, the prefabricated scaffolding does require design registration

-

Formwork should be monitored as it is loaded to check for indications of potential failure or collapse, and that vertical and horizontal movements do not exceed specifications, and visually remain as per the intent of the design

-

Competent persons should be on site during concrete placement to make any emergency adjustments or repairs. The concrete placement should stop during adjustments and repairs at the discretion of a competent person

Activity |

Competency |

Record |

|---|---|---|

Installation, alteration, dismantling of formwork / falsework |

Qualified Carpenter - minimum Certificate III in Carpentry (or equivalent) |

Subcontractor Handover certificate |

Pre-use inspection, immediately after installation |

Structural Engineer |

Formwork Structural Certificate |

Pre-use inspection, immediately prior to loading |

Structural Engineer |

Formwork Structural Certificate |

Continuous monitoring during loading |

Qualified Carpenter - minimum Certificate III in Carpentry (or equivalent) or Structural Engineer |

N/A |

Inspection prior to dismantling |

Structural Engineer |

Formwork Structural Certificate & Written confirmation from the Structural Engineer responsible for the design in conjunction with the formwork engineer verify in writing that the permanent structure is self supporting |